NOTE: At the moment, only the sensors mentioned below are included in CanAirIO firmware. Other sensors please submit a issue.

Preparing the sensor for first use

In order to prevent address conflicts when using multiple sensors, we have prepared 8 groups with a total of 23 addresses. If necessary, You can use “change_sensor_iic_addr.ino” in the library file “example”,to switch by modifying the group serial number configuration of “changeI2cAddrGroup()”. After the serial port information displays “IIC addr change success!”, power on again.

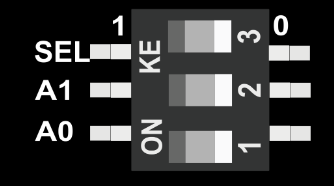

First of all, prepare the swiches depending on the sensor to be used.

SEL = 0 A1 = See the following table. A2 = See the following table.

| A0 | A1 | I2C Address | Sensor asigned |

|---|---|---|---|

| 0 | 0 | 0x78 | CO |

| 0 | 1 | 0x79 | none |

| 1 | 0 | 0x7A | NH3 |

| 1 | 1 | 0x7B | NO2 |

The address group must be assigned, by software, to group 7.

Why is it necessary to make this change?

As CanAirIO can use several sensor models, the i2c addresses can match. This is a problem, which creates a malfunction in the device. For example, in sensor BME280, BMP280, BME680, they use addresses 0x77, 0x76 and 0x77, respectively. The standard address, with which the DFRobot gravity sensors are configured, is 0x77, if not changed, and used in combination with the BME680, a conflict occurs.

Group changer sketch

Please load this sketch to change default group to 7, following this instructions:

In platformio, create a new proyect, and place this code in main.cpp:

/*

* @file changeSensorI2CAddr.ino

* @brief The sensor proactively reports all the data, only i2c communication can use this demo.

* @n Experimental mode: connect sensor communication pin to the main controller and burn

* @n Communication mode select, DIP switch SEL: 0: I2C, 1: UART

* @n Group serial number address in the group

* @n A0 A1 DIP level 00 01 10 11

* @n 1 0x60 0x61 0x62 0x63

* @n 2 0x64 0x65 0x66 0x67

* @n 3 0x68 0x69 0x6A 0x6B

* @n 4 0x6C 0x6D 0x6E 0x6F

* @n 5 0x70 0x71 0x72 0x73

* @n 6 (Default address group) 0x74 0x75 0x76 0x77 (Default address)

* @n 7 0x78 0x79 0x7A 0x7B

* @n 8 0x7C 0x7D 0x7E 0x7F

* @n i2c address select, default to 0x77, A1 and A0 are grouped into 4 I2C addresses.

* @n | A0 | A1 |

* @n | 0 | 0 | 0x74

* @n | 0 | 1 | 0x75

* @n | 1 | 0 | 0x76

* @n | 1 | 1 | 0x77 default i2c address

* @n Experimental phenomenon: serial print all the data

* @copyright Copyright (c) 2010 DFRobot Co.Ltd (http://www.dfrobot.com)

* @license The MIT License (MIT)

* @author PengKaixing(kaixing.peng@dfrobot.com)

* @version V1.0

* @date 2021-03-28

* @url https://github.com/DFRobot/DFRobot_MultiGasSensor

*/

#include "DFRobot_MultiGasSensor.h"

/*

A0 A1 I2C Address Sensor asigned

0 0 0x78 CO

0 1 0x79 none

1 0 0x7A NH3

1 1 0x7B NO2

*/

#define I2C_ADDRESS 0x7B //0x7B for NO2, 0x7A for NH3, 0x78 for CO

DFRobot_GAS_I2C gas(&Wire ,I2C_ADDRESS);

uint8_t scan()

{

Wire.begin();

for(uint8_t address = 1; address < 127; address++ ) {

Wire.beginTransmission(address);

if (Wire.endTransmission() == 0)

return address;

}

return 0xff;

}

void setup() {

Serial.begin(115200);

gas.setI2cAddr(scan());

//Sensor init, init serial port or I2C, depending on the communication mode currently used

while(!gas.begin())

{

Serial.println("NO Deivces !");

delay(1000);

}

//Change i2c address group

while(gas.changeI2cAddrGroup(7)==0)

{

Serial.println("IIC addr change fail!");

delay(1000);

}

Serial.println("IIC addr change success!");

}

void loop(){

}

Platformio.ini example. Please, adapt it to your esp32 board.

; PlatformIO Project Configuration File

;

; Build options: build flags, source filter

; Upload options: custom upload port, speed and extra flags

; Library options: dependencies, extra library storages

; Advanced options: extra scripting

;

; Please visit documentation for the other options and examples

; https://docs.platformio.org/page/projectconf.html

[env:esp32doit-devkit-v1]

platform = espressif32

board = esp32doit-devkit-v1

monitor_speed = 115200

monitor_filters = time

framework = arduino

lib_deps =

https://github.com/DFRobot/DFRobot_MultiGasSensor.git

After run the sketch, by monitor serial, if all the proces run correctly, you can se the message: IIC addr change success!

Now you can load the CanAirIO firmware.

Oficial documentation from manufacturer, ban be found here

Features

Factory calibrated, accurate measurement High sensitivity, low power consumption Excellent stability and anti-interference Use I2C mode only Long service life(2 years) Compatible with 3.3~5.5V main controllers 32 modifiable I2C addresses Reverse connection protection Temperature compensation Threshold alarm

Specifications

Detection Gas: CO, O2, NH3, H2S, NO2, HCL, H2, PH3, SO2, O3, CL2, HF(Need to change different probe) Working Voltage: 3.3~5.5V DC Working Current: <5mA Output Signal: I2C Detection error: ±10% of output value or ±5% of full scale (whichever is greater) Working Temperature: -20~50℃ Working Humidity: 15~90%RH (non-condensing) Storage Temperature: -20~50℃ Storage Humidity: 15~90%RH (non-condensing) Lifespan: >2 years (in the air) Adapter Plate Size: 37×32mm

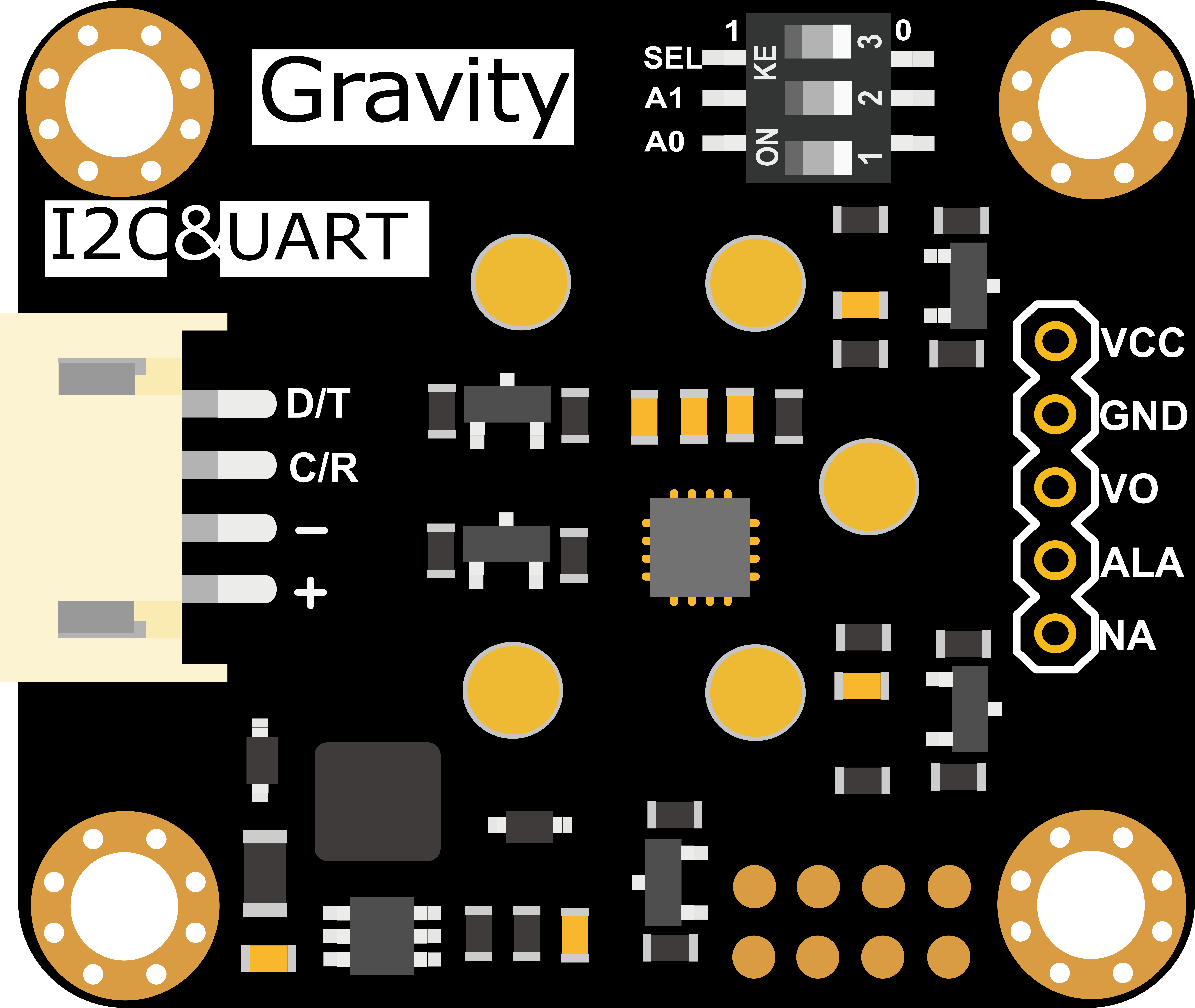

Board Overview

Smart Gas Sensor Terminal

| Label | Name | Function | |

|---|---|---|---|

| 1 | D/T | I2C data line SDA | |

| 2 | C/R | I2C clock line SCL | |

| 3 | GND | Ground | |

| 4 | + | Power supply + (3.3-5V compatible) |

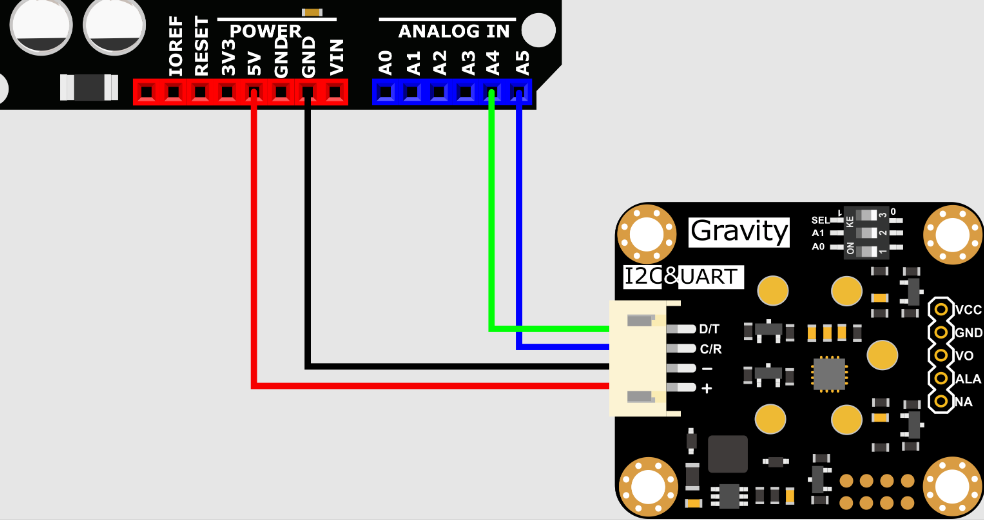

Connections

Characteristic Parameters

| SKU | SEN0466 | SEN0469 | SEN0471 |

|---|---|---|---|

| Type | CO | NH3 | NO2 |

| Detection Range | (0-1000) ppm | (0-100) ppm | (0-20) ppm |

| Resolution | 1ppm | 1ppm | 0.1ppm |

| Response Time (T90) | ≤30S | ≤150S | ≤30S |

Credits

Author: @roberbike

Maintainers: @hpsaturn